Powder Coating Principle of Operation

- Share

- Issue Time

- Jun 29,2014

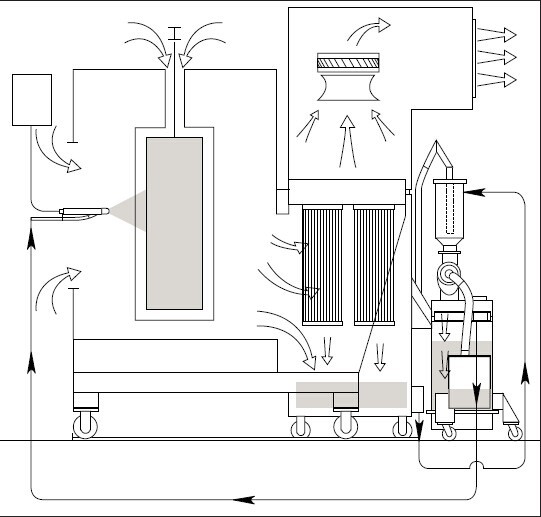

The electrostatic application of powder coating to a part

begins with fluidization. Fluidization is a process where

powder being sprayed mixes with compressed air,

enabling it to be pumped from a container and supplied to

the spray guns. The powder flow is regulated by controlling

the air supplied to the pump. The powder supplied to

the spray gun is charged using either a corona or tribocharging

gun. Charged powder moves to the grounded

workpiece with the help of air supplied to the guns and

the airflow in the booth.

When the powder particles come close to the part, an

electrostatic attraction between the charged powder particles

and the grounded part adheres powder to the part.

The coated part then passes through an oven and is

cured. The oversprayed powder is contained within an

enclosure and drawn into the primary filter cartridges by a

centrifugal fan. Circulating air, now free of powder, is discharged

through high-efficiency final filters into the plant

as clean air. The primary filter cartridges are periodically

reverse-pulsed to remove oversprayed powder. The powder

is then sieved and supplied back to the guns to provide

extremely efficient material for use again. A simple diagram

showing how this process works is shown in Figure