Entry Doors

- Share

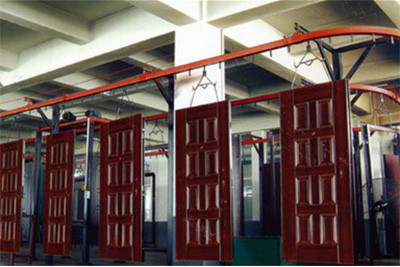

POWDER COATING FOR ENTRY DOORS

Powder coated products are more resistant to chipping, scratching, UV rays, and corrosive elements. This process uses a dry powder of polymer resins, pigments, leveling agents, and other additives that is ground into a uniform powder similar to baking flour.

Electrostatic spray deposition is used to apply the powder coating to the metal product. A spray gun with an electrostatic charge is used to apply the powder particles which are attracted to the grounded metal.

After application of the powder the material enters a curing oven where with the addition of heat the coating chemically reacts and forms a “skin” on the material. This thermal bonding allows for a more uniform coverage no matter whether you have a horizontal or vertical surface.

The powder coat bonding is much thicker than standard wet paint, which is generally no more the .5 to 1 mil in thickness (a mil is one one-thousandths of an inch). Powder coat finishes range from 2 mil to 10 mil in thickness.

Powder coating process does not require a liquid carrier (solvent) like liquid coatings this system emits near zero volatile organic compounds . This means powder coating is environmentally friendly since no organic compounds are released into the air.