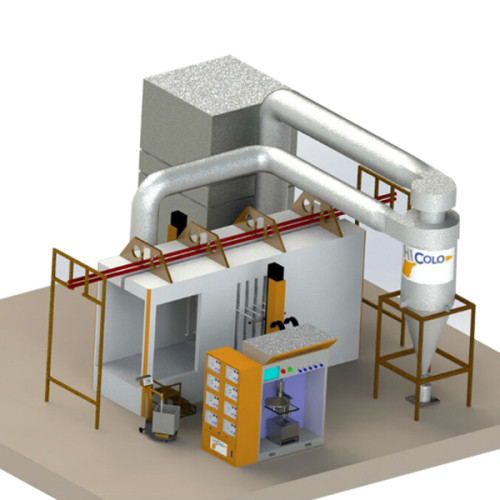

Automatic Powder Coating Cyclone Booth System

- Model

- COLO-Mono Cyclone/COLO-2000D/COLO-800D-A

Item specifics

- Delivery Time

- 30 Working Days

- Shipping

- By Sea

- Application

- Metal Finishing Industry

Review

Description

Stainless Steel Automatic Powder Coating Cyclone Booth System

Application

The Automatic Powder Coating Spray System includes:

COLO-800D-A automatic powder coating gun and control cabinet,

COLO-2000D powder coating reicprocator,

COLO-mono cyclone automatic powder spray booth,

PP plastic automatic powder coating booth with mono cyclone help you change the color faster and save the more powder, give you better soluctiones of your industrial powder coating job.

Automatic Powder Spray Booth

Excellent Features

1. Cyclone powder booth provides powerful air extraction and equal airflow distribution for perfect powder coating job.

2. Mono cyclone achieves recycling efficiency up to 98%, a great saving of powders, a quick cleaning takes around 15 minutes.

3. With the discharge device of "large-diameter cyclone separator + after filter unit" makes the least powder accumulation and the most environmental-friendly emission.

4. There's air clean system continuously transports over sprayed powder from the booth floor, quickly recycling it back to the powder feed container.

|

Model

|

COLO-Mono Cyclone

|

|

Working Dimension (mm)

|

800width x 2000 height x 6000 depth mm

|

|

Weight

|

4000kg

|

Voltage | 380V/220V. customized as local |

Fan Power | 5.5kw/set, 2 sets total |

Frequency | 50-60Hz |

Filters | Polyester, 12pcs |

Filter cleaning system | Pneumatic |

Booth Material | Wall: Stainless Steel |

Cyclone Material | Stainless Steel |

COLO-800D Automatic Powder Coating Gun System

Excellent Features

1. COLO-800D Intelligent controller has one-touch preset buttons suitable for beginners handling different metal shapes, including panel-coating, corner-coating, re-coating.

2. The 100kv spray gun powerfully charge powders delivers high transfer efficiency, increase powder utilization.

4. A central control cabinet combines all gun controller for integrated operation, enbales to set parameters only at one host unit to control whole system.

5. The quantity of the control units installed in the cabinet can be customized as your production needs.

|

Model

|

COLO-800D-A

|

|

Power Range |

220V/110V |

|

Frequency

|

50HZ/60HZ |

Gun Weight | 500g |

|

Temperature range in use |

-10 ℃+50 ℃ |

Rated output voltage | 24VDC |

Input Voltage | 200kv |

Maximum output current | 180Ua(max) |

Maximum output voltage | 0-100KV (adjustable) |

Maximum powder injection | 650g/min |

Polarity | negative (-) |

COLO-2000D Powder Spray Reicprocator

Excellent Features

1. COLO Reciprocator is designed for consistent and uniform coating in automatic production line.

2. Spraying guns' movement is programmed in various speeds & strokes to suit conveyor speed & object height respectively.

3. carries a certain quantity of spray guns for up-and-down motion, delivers excellent uniformity and efficiency of powder coating.

4. The digital control system can be memorized for 80 storable programs, Working parameters are monitored on a user-friendly panel.

5.Driven by frequency motor, solid and maintenance free, allows to carry 2-12pcs spray gun, making smooth movement.

|

Model |

COLO-2000D |

|

Power Supply

|

AC 220V/110V 50-60Hz

|

|

Motor Power

|

1.1kw

|

|

Speed Range

|

0-50m/min(0-0.8m/s)

|

Max. Loading Capacity | 25kgs |

Stroke Length | 1.5m/2m/2.5m |

Standard Size | 850*680*2970mm |

Reciprocator Weight | 295kg |