COLO-6200 Highly Efficient Automatic Powder Coating Supply Center

- Model

- COLO-6200

Item specifics

- Delivery Time

- 15 Working Days

- Shipping

- By Sea

- Application

- Metal Finishing Industry

Review

Description

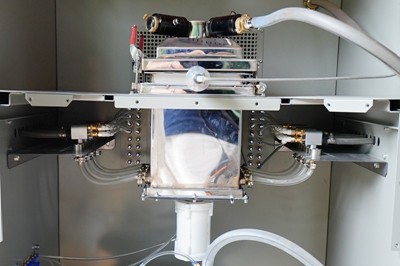

COLO-6200 Highly Efficient Automatic Powder Coating Supply Center

COLO-6200 highly efficient automatic powder feed center is specially designed for fast color change in the automatic powder coating line, by powerful cleaning of spray gun, powder hose, and injector during color change, the powder feed center greatly enhance the automation and improve productivity. A very compact design and can be adapted to any system layout.

Product Details

Integrated PLC Control System

PLC control system with touch screen integrates all functions, It control everystep of powder coating line, automatic cleaning of spray guns, powder hoses, injectors during color change, reduce manpower and increase efficiency.

Box Feed Powder Funnel

Allows directly placing the original powder carton on the funnel, flexible for color changing, no need to clean the powder container, increasing the production efficiency.

Powder Supply Hopper

Fresh and recovered powders will enters into the integrated powder hopper, whose powder level detection feature guarantees a constantly available powder quantity. With optimal fluidization condition for quality coating results. Closed powder hopper ensure dustless working environment.

Ultrasonic Siever

Ultrasonic sieving of fresh powders and recovery powders, dissolving and loosening of powder accumulations for even powder flow. Free-swinging sieve surface causes gentle sieving and requires less energy.

Product Parameters

|

Model

|

COLO-6200

|

|

Voltage

|

110V/220V, 1Phase (can be customized)

|

|

Total Power

|

100w

|

Powder Hopper Size | 310*240*270mm |

Standard Mesh Size | 80 mesh (on request) |

Ultrasonic frequency | 38kHz |

Product Video