Customized Walk in Manual Powder Coating Line

- Model

- COLO-Line-Australia

Item specifics

- Delivery Time

- 30 Working Days

- Shipping

- By Sea

- Application

- Metal Finishing Industry

Review

Description

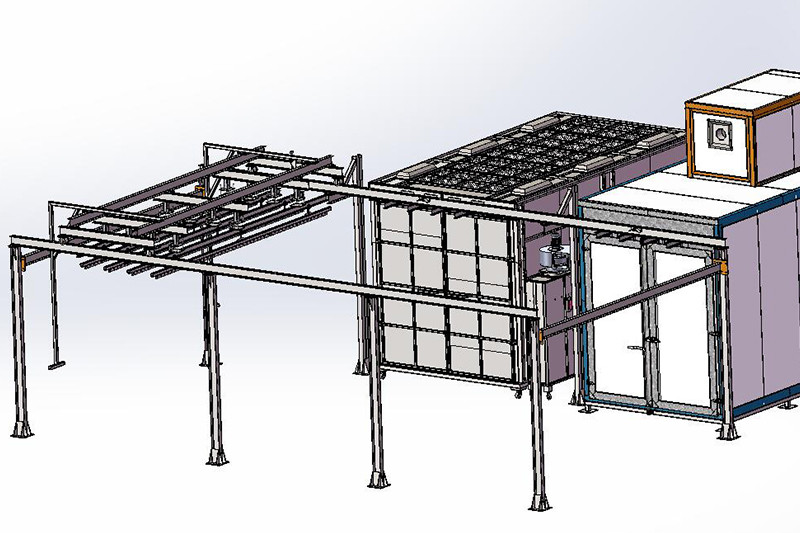

Customized Walk in Manual Powder Coating Line

Application

The Walk in Manual Powder Coating Line includes:

COLO-191S powder coating machine,

COLO-walk in powder coating booth,

COLO-top track powder curing oven,

suitable for powder coating large and heavy workparts or big batches, it is specially designed for limited factory space.

The manual powder coating line is specially designed and manufactured by COLO for our Australia customer, it is ideal for continuous production based on manual operation. Ideal for big or complex workparts that requires precise coating jobs, also suitable for batch production of small parts. The powder coating conveyor is horizontal-pull type, which requires you less efforts to move heavy objects for production processes.

COLO-191S Powder Coating Machine

Excellent Features

1. Digital valve control technology for fast and precise adjust the powder output and atomization, flexibly control voltage and current.

2. 3 Pre-set application programs, flat parts coating, corner coating and re-coating. Allows experienced users to create and store 20 application programs which are optimized for their parts and powders.

3. Long-lasting 100kv spray gun maximizes the electrostatic charging capacity, provides high transfer efficiency and saves materials.

4. The box feed type is ideal for multi-color application with quick change operations.

5. Comes with full array of nozzle assortment, including flat, round spray nozzles with different size deflectors, and extension nozzles.

|

Model

|

COLO-191S

|

|

Power Range |

220V/110V |

|

Frequency

|

50HZ/60HZ |

Gun Weight | 500g |

|

Temperature range in use |

-10 ℃+50 ℃ |

Rated output voltage | 24VDC |

Input Voltage | 200kv |

Maximum output current | 180Ua(max) |

Maximum output voltage | 0-100KV (adjustable) |

Maximum powder injection | 600g/min |

Polarity | negative (-) |

COLO-Walk in Powder Spray Booth

Excellent Features

1. It is walk in type powder booth with doors, allows operators walking in for the coating of large workparts.

2. Powder reclaim is achieved by a recovery stage, which is combined with 12pcs pieces of high precision filters, reach high powder recycling rate.

3. Filter cleaning is automatically done through pulse solenoid valve for extended filter life.

4. Configured with PLC controller, offers all the functions you need, control the fan working, set interval and time of pulse jet for filter cleaning.

|

Model

|

COLO-walk in powder coating booth

|

|

Working Dimension

|

L5.5m x W2.8m x H3.1m

|

|

Opening Dimension

|

W2.8m x H2.9m

|

Air Flow | 4050m^3/h |

Material | SPCC/t=1.5mm, with door |

Bottom Frame | 8# square tube |

Booth Inner Frame | 8# square tube |

Recovery System | Filter Cartridge (12pcs) |

Fan Motor | 3kw, 4sets |

COLO-Top Track Powder Coating Oven

Excellent Features

1. Gas heating oven is more clean and cost-saving, quick raising of high temperature increase production efficiency.

2. A powerful circulation fan makes even temperature in inner chamber ensure high quality curing results.

3. The curing oven is made of 100mm thickness rock wool board of the interlayer, keep long time heat preservation.

4. Applies PLC system offering a precise and reliable heating process, easy to control the working of fan, setting the heating time and temperature.

5. Designed with overhead track system for easy movement by manual, allows loading a plenty of heavy elements.

|

Model

|

COLO-top track powder coating oven

|

|

Working Dimension

|

Width 2.5m x Height 3.1m x Depth 5.6m

|

|

Materal

|

100mm rock wool board

|

Voltage | 380V/220V. customized as local |

Controller | Digial PLC Controller |

Gas Burner | 300,000 kcal/h, RIELLO brand |

Fan Motor | 11kw, 1 set |

Air Flow | 12000-14000m^3/h |

Product Features & Applications

This manual powder coating line can achieve big production of small workparts, or large dimension, heavy objects, as the parts movement are through overhead track system with leas manual efforts. They do powder coating application for small metal frames and big panels.