Manual Electrostatic Powder Coating Plant

- Model

- COLO-Line-Malaysian

Item specifics

- Delivery Time

- 30 Working Days

- Shipping

- By Sea

- Application

- Metal Finishing Industry

- Size

- Customized

Review

Description

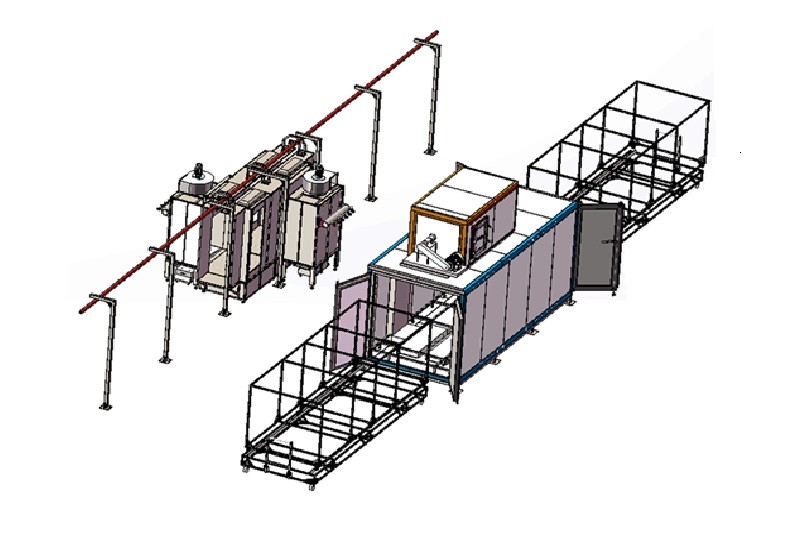

Manual Electrostatic Powder Coating Plant

Application

The Manual Electrostatic Powder Coating Plant includes:

COLO-191S powder coating spray gun,

COLO-pass thru powder coating booth,

COLO-gas powder coating batch oven,

is specially designed for manual coating of big dimension or long length workparts in batches. Sizes and specially configurations can be customized as your productions.

This powder coating plant is specially designed for manual coating of big dimension or long length workparts in batches. Transport the workparts by manual and powder coating by electrostatic guns, which minimize budget and labor efforts.

COLO-191S Powder Coating Machine

Excellent Features

1. Digital valve control technology for fast and precise adjust the powder output and atomization, flexibly control voltage and current.

2. 3 Pre-set application programs, flat parts coating, corner coating and re-coating. Allows experienced users to create and store 20 application programs which are optimized for their parts and powders.

3. Long-lasting 100kv spray gun maximizes the electrostatic charging capacity, provides high transfer efficiency and saves materials.

4. The box feed type is ideal for multi-color application with quick change operations.

5. Comes with full array of nozzle assortment, including flat, round spray nozzles with different size deflectors, and extension nozzles.

|

Model

|

COLO-191S

|

|

Power Range |

220V/110V |

|

Frequency

|

50HZ/60HZ |

Gun Weight | 500g |

|

Temperature range in use |

-10 ℃+50 ℃ |

Rated output voltage | 24VDC |

Input Voltage | 200kv |

Maximum output current | 180Ua(max) |

Maximum output voltage | 0-100KV (adjustable) |

Maximum powder injection | 600g/min |

Polarity | negative (-) |

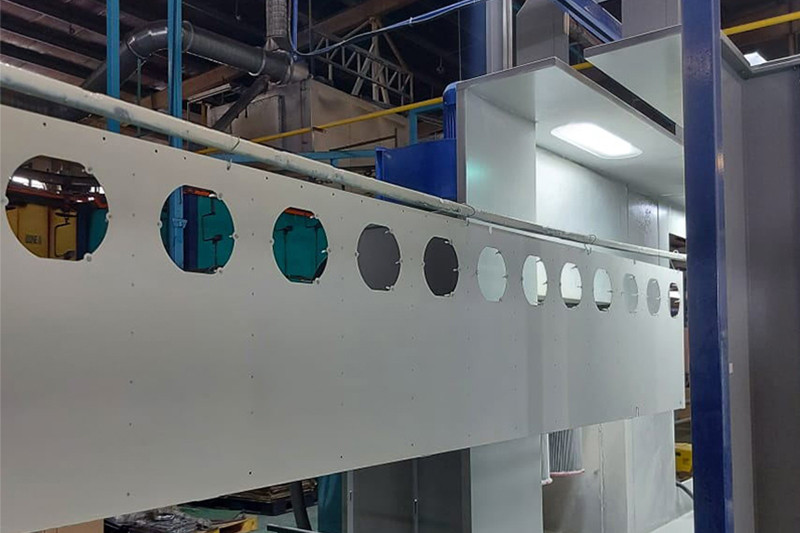

COLO-Pass Thru Powder Coating Booth

Excellent Features

1. Pass thru powder coating booth allows parts enter the booth from one entrance and exit from the other through overhead track while recieving powder coating from bilateral stations, suitable for long lenth workparts.

2. The powder spray booth configured with double filter stages for highly-efficient powder recovey, as well as ensures cleaning working environment.

3. A removable powder collector beneath the filter stage will holds oversprayed powders and can be taken out for recycling use.

4. Full parameters and functions can be handled on the PLC panel, such turning on / off fan, setting pulse-jetting time and interval, light on/off, emergency stop etc.

|

Model

|

COLO-pass thru powder coating booth

|

|

Opening Size

|

W0.8m x H2m

|

|

Inner Size

|

width 1.12m x depth 4m x height 2m

|

Air Flow | 5000m^3/h |

Material | SPCC/t=1.5mm |

Fan Motor | 5.5kw, 2sets |

Recovery Hopper | 2 sets |

Recovery System | Filter Cartridge (12pcs) |

Fan Motor | 3kw, 4sets |

COLO-Gas Batch Powder Coating Oven

Excellent Features

1. This powder coating oven designed wth ground trolleys that allows loading a group of workparts for big production.

2. Made of 100mm thick rock wool board, the oven keeps good heat preservation.

3. A circulation fan cycles hot air uniformly that results quality curing effect.

4. PLC system provides a precise and reliable heating process with easy setting of temperature and time.

5. Gas fired powder coating oven features quck-heating, energy-saving, reducing operating cost and curing more parts everyday.

|

Model

|

COLO-batch powder coating oven

|

|

Working Dimension

|

Width 2m x Height 2m x Depth 6m

|

|

Materal

|

100mm rock wool board

|

Voltage | 380V/220V. customized as local |

Controller | Digial PLC Controller |

Gas Burner | 200,000 kcal/h, RIELLO brand |

Fan Motor | 7.5kw, 1 set |

Air Flow | 8000m^3/h |

Product Features & Applications

The powder coating line is specially designed and manufactured by COLO for our Malaysia customer, they do powder coating application for aluminum profiles and metal frames, sheet metal, etc.