Manual Powder Coating Equipment Package

- Model

- COLO-800D, COLO-1517, COLO-1864

Item specifics

- Delivery Time

- 15-20 Working Days

- Shipping

- By Sea

- Application

- Metal Finishing Industry

Review

Description

Manual Powder coating Equipment Package

Application

The Manual Powder Coating Equipment Package includes:

COLO-800D powder

coating machine,

COLO-1517 powder coating booth,

COLO-1864 powder

coating oven,

suitable for small and medium scale production with easy

operation. It is efficient for powder coating metal parts such as wheel rims, auto parts, furniture products, etc.

COLO-800D Powder Coating Machine

Excellent Features

1. Voltage can be easily set by buttons from 0-100kv, the voltage and amperage values will be shown on the digital display for accurate reading.

2. With 3 one-touch intelligent buttons, application programs switches automatically between panel coating, corner coating and recoating.

3. 100kv spray gun maximizes the electrostatic charging capacity, provides high transfer efficiency.

4. Equipped with a 60ml fluidizing powder hopper, delivers uniform powder flow.

5. Comes with full array of nozzle assortment, including flat, round spray nozzles with different size deflectors, and extension nozzles.

|

Model

|

COLO-800D

|

|

Power Range |

220V/110V |

|

Frequency

|

50HZ/60HZ |

Gun Weight | 500g |

|

Temperature range in use |

-10 ℃+50 ℃ |

Rated output voltage | 24VDC |

Input Voltage | 200kv |

Maximum output current | 180Ua(max) |

Maximum output voltage | 0-100KV (adjustable) |

Maximum powder injection | 600g/min |

Polarity | negative (-) |

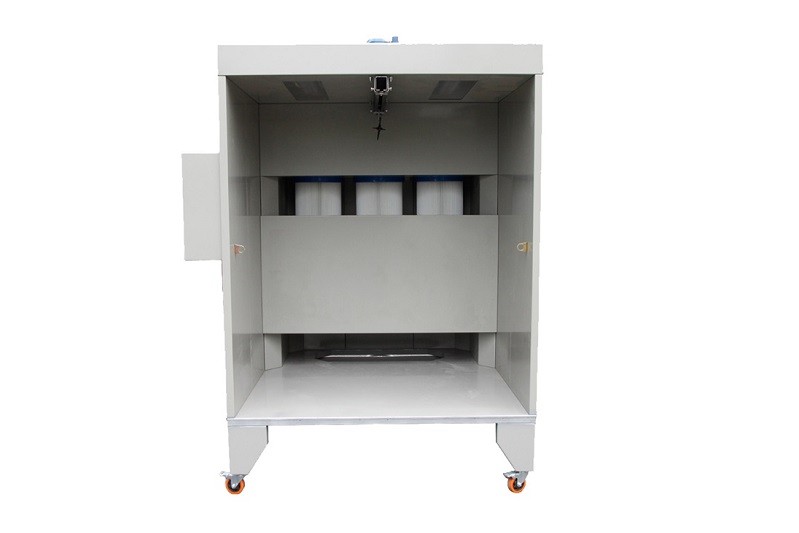

COLO-1517 Powder Spray Booth

Excellent Features

1. Consists of 3 pcs cartrifge filters for high efficiency powder recovery that makes clean and dustless working condition.

2. The compact powder booth is made of durable steel plate by powder-coated, sturdy and long lifespan.

3. Applies PLC control for filter cleaning, fan on/off and other functions

4. Designed with powder recovery hopper for easy emptying and recycling.

5. A high-performance fan efficiently circulate air with low noise and less energy.

|

Model |

COLO-1517 |

|

Operating Dimensions |

Width1500 * Depth1000 * Heght1700mm |

|

Overall dimensions |

Width1600 * Depth2000 * Heght2250mm |

|

Power Supply |

220V/380V, 3Phase, 50-60HZ |

Fan Power | 2.2kw |

Cartridge Filter | 3 pcs, Quick-release Type, Polyester Material |

Filter Cleaning | Pneumatic |

Air Consumption | 4000m^3/h |

COLO-1864 Powder Coting Oven

Excellent Features

1. 0.75kw Circulation fan circles the hot air to warm the powder coating oven interior, minimize temperature difference and guarantee uniform-heated chamber

2. Made of 100mm thick rockwool board, effectively minimums temperature dropping.

3. The PLC control system offers user-friendly interface for users to set the required temperature and heating time accurately.

4. Standardly equipped with a pair of carts: internal one and external one, for easy handling of workparts.

|

Model

|

COLO-1864

|

|

Working Dimension (mm)

|

Width1600 * Heght1800 * Depth1400mm

|

|

Overall Dimension (mm)

|

Width1900 * Heght2200 * Depth1700mm

|

Voltage | 220V/380V(50-60Hz) |

Heating Power | 18kw |

Warm-up Time | 15-30min (180°C) |

Temperature stability | < ± 3-5°C |

Temperature max. | 250°C |

Circulation/ Air flow | Vertical ,Variable through holes on the walls |

Transportation | Trolley |